Power Generation/Steam Power

Review: Lesson 1

The first Lesson was an Introduction to the principles of Electrical power generation. Here are some points you need to remember from lesson 1.

- Important electric power generation definitions

- Different sources of energy

- Electrical energy generation arrangement

Preview: Lesson 2

This Lesson is about Steam Power station. The student/User is expected to understand the following at the end of the lesson.

- Basics:

- Arrangements:

- Cooling:

- Location:

- Efficiency:

Definition, advantages & disadvantages.

Components that make up a steam power station.

Wet and dry cooling methods.

Factors influencing selection of construction site.

How efficient this power station is.

|

Figure 1:Bobov Dol Thermal Power Plant in Bulgaria showing three cooling towers ( Click on image to view full size image ) |

Introduction: Steam/Thermal Power station

A steam/thermal power station uses heat energy generated from burning coal to produce electrical energy. This type of power station is widely used around the world.

This power station uses the Rankine cycle. This is the cycle of the steam produced in the boiler, then taken to the Steam turbine (prime mover). From the turbine the steam is cooled back to water in the Condenser, the resulting water is fed back into the boiler to repeat the cycle.

Because of the abundance of fuel (coal), this kind of power station can be used to produce large amounts of electrical energy. In most countries these power stations are used as base load power stations. This is because steam power stations are slow to start and can not be used to cater for peak loads that generally occur for a short duration.

These power stations (together with nuclear power stations) are kept running very close to full efficiency for 24 hours a day (unless they are being maintained). They have typical life of 30 to 40 years (although most governments have reduced this number to 35 years).

Pros & Cons: what this power station presents

| Advantages | Disadvantages |

|---|---|

| Cheap coal is used | Air pollution from smoke fumes |

| Can be installed anywhere near fuel & water supply | Costs more to run compared with other types of power stations |

| Requires less construction space | |

| Cost for Generation is less |

Future generations will have to learn to depend less and less on this type of electricity generating power station, due to a fast increasing depletion of fuels (coal and oil). As other types of power stations become more efficient it should be possible to completely abandon the use of this type of power station.

| Stage 1: Coal & Ash handling

This stage is seen as the entrance and exit of fuel( coal )used. The initial handling treatment and storage of coal and the final handling and disposal of Ash.

Stage 2: Steam Generating Plant This stage is seen as the energy loss stage. The steam creation by heat accounts for the greater percentage of power station in-efficiency.

Stage 3 & 4: Steam turbine & Alternator/Generator This stage is seen as the energy conversion stage. The steam turbine converts steam energy to rotational mechanical energy, while the Alternator/Generator converts rotational mechanical energy into electrical energy.

Stage 5: Feed water & Cooling This stage is seen as the recycling stage. Steam used in boiler chamber is condensed back to water for re-use.

| |||||||||||||||||||||||||||||||||||||

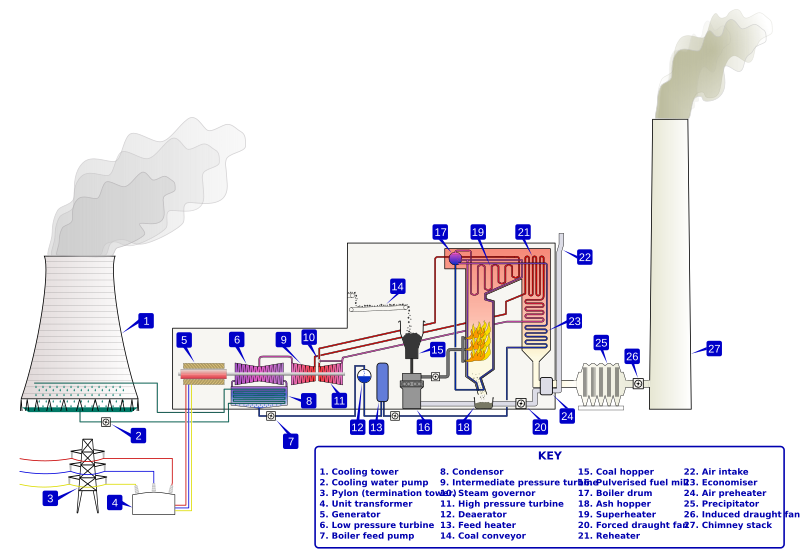

| This schematic diagram must be properly understood. it is the basis upon which Steam power station designs are done. the individual power station complexity may differ slightly to the schematic and yet over and above that will use the same principle. | |||||||||||||||||||||||||||||||||||||

This is the conventional cooling method used in most steam power stations. Steam of very high purity is cooled inside the condenser and is returned to the boiler(Rankine cycle).

The condenser itself uses cold water and employs the principle of heat exchange. As the cool water is returned to the boiler, the hot water in the condensor is pumped to the cooling tower. Here water is sprayed and thus falls down to the water pond under the cooling tower. As the water falls it is cooled by the natural cold air. The cooled water is pumped back to the condenser, and the cycle is repeated. This method uses a lot of water through evaporation.

| Water consumption |

|---|

| ≈ 2.5 lt/kWh |

This is the more preffered Cooling method which is now being implemented in most new Steam power stations. Steam is circulated inside a radiator-like heat exchanger and is cooled by the natural cold air blown (naturally or using draught fans) between pipes of the heat exchanger. The cooled/condensed steam is returned to the boiler(Rankine cycyle).

This method greatly decreases water wastages through evaporation by almost 84% of the wet cooling method. It is called Direct dry cooling since the condenser has been eliminated completely. This method is favored where water is scarce.

| Water consumption |

|---|

| ≈0.4lt / 1kWh |

The first Indirect Dry cooling method is called Wet cooled condenser.

Here the condenser is still used to cool steam that is pumped back to the boiler. The hot water from the condensor is then pumped to Heat exchangers in the cooling tower and natural ventilation is used to cool the water which can then be pumped back to the condenser. Notice that water consumption here is double that consumed in the direct dry cooling method.

| Water consumption |

|---|

| ≈0.8lt / 1kWh |

The second Indirect Dry cooling method is called Jet cooled condenser.

Here the exhaust steam leaving the low-pressure turbine condensed by a jet spray of cold water. the resulting hot water collected is through heat exchangers in the cooling tower. The cooled water is sent back to the boiler. Notice that water consumption is equal to the previous cooling method.

| Water consumption |

|---|

| ≈0.8lt / 1kWh |

The following is a list of factors that influence the selection of site for constructing a Steam power station:

1. Supply of fuel:

- The station must be located close to coal mines to reduce transportation cost of fuel.

2. Availability of water:

- The station must be located near a river bank or canal for continous water supply.

3. Transportation facilities:

- The station must be well connected to major transport routes eg Rail or Road.

4. Cost & type of land:

- The land must have a good bearing capacity for heavy equipment and yet be cheap enough to purchase.

5. Distance from populated areas:

- The station must be located as far away from populated areas as possible due to air pollution.

6. Nearness to load centers:

- In order to reduce the transmission cost the plant should be located near load centers.

This type of power station has very high energy losses due to great heat loss in the boiler and condensor. the following equation is used to calculate power station efficiency:

Thermal efficiency

the above can be re-written as follows:

The above generally works out to ±30% for steam power stations.

you can further calculate overall efficiency as follows:

the above can be re-written as follows:

The above generally works out to ±29% ( 1% loss at the generator ) for steam power stations.

Sir, From steam table we can calculate the Total heat of Superheated steam at corresponding Steam inlet pressure of Turbine and Outlet of turbine. As per example --(1) steam inlet pressure of turbine is 32 kg/cm2, 450 deg. centigrade. steam outlet pressure of turbine is 10 kg/cm2 saturated. (2)steam inlet pressure of turbine is 60 kg/cm2, 450 deg. centigrade. steam outlet pressure of turbine is 10 kg/cm2 saturated.

So now if we calculate heat from Steam Table, difference of Heat of (2) is coming Less than (1). Why this happen ? Power generated is less in (2) even though pressure is high. Than why we should go high pressure.

Thanks, M B Kshatriya. Mobile - 76000 51274.

References

- This resource is prepared from Lecture notes by Thuvack.

- V.K Mehta & Rohit Mehta :- Principles of Power systems (1st ed.). S.CHAND .ISBN 81-219-2496-0